2005 Chevy Silverado 2500HD Bolt Pattern: Everything You Actually Need to Know

- Ford Expedition Years to Avoid A Mechanic’s Complete Guide (2026) - January 28, 2026

- 5 Signs You Need to Change Your Transmission Fluid Chevy Silverado - January 27, 2026

- Ford Maverick Years to Avoid: Worst & Best Models (2022-2026) - January 26, 2026

Last Saturday, this guy pulled into my shop with a set of brand new wheels in his truck bed. Beautiful wheels. Chrome. Looked expensive. Still had the stickers on them. Can you mount these for me?

Sure thing. I grab one, walk over to his 2005 Silverado 2500HD, line it up with the hub, and—Wait. Something’s off. Holes don’t line up. Not even close.

Turns out he bought them off some dude on Facebook. “They’re for a Chevy truck,” the seller said. Four hundred bucks. No returns. Wrong bolt pattern. Eight-lug versus eight-lug, but with different diameters. Can’t make ’em fit. Not happening. He ended up selling them locally for two hundred dollars. Ate a two-hundred-dollar loss because he didn’t check one simple measurement before buying. This happens more than you’d think. Your 2005 has a specific bolt pattern. Get it wrong, those wheels aren’t going on. Doesn’t matter how good the deal is. Doesn’t matter how cool they look.

So yeah. Let’s talk bolt patterns. Because apparently, people still need this explained.

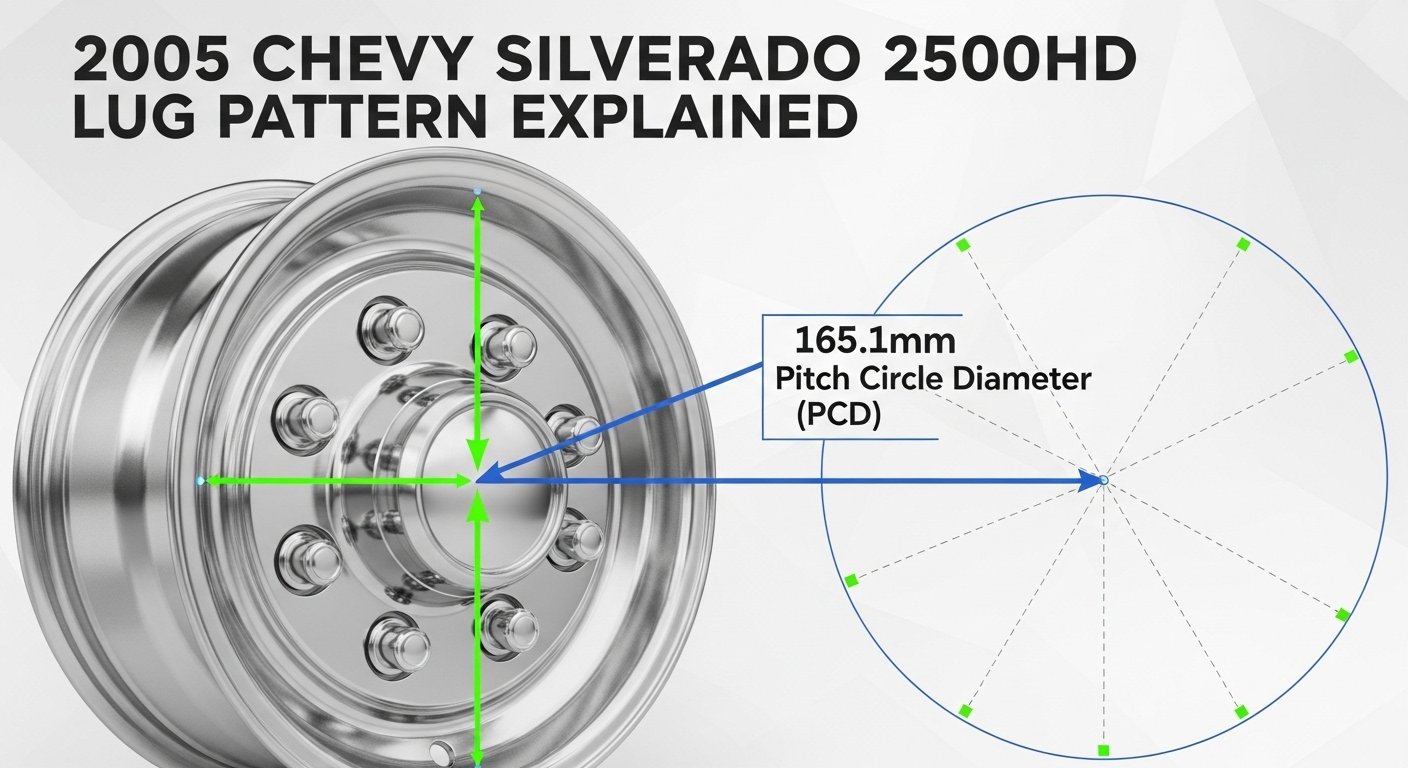

Alright, What’s the Actual Bolt Pattern?

Your truck uses 8×6.5 inches.

Metric? That’s 8×165.1mm.

Breaking it down:

- 8 = how many lug bolts you’ve got

- 6.5 inches = the circle diameter they form

People also call this the “lug pattern” or “PCD.” Same thing. Different names. Don’t let anyone confuse you with jargon.

Now here’s what matters. GM used this 8×6.5 pattern on their heavy-duty trucks from about ’99 to 2010. Your 2005? Right in that window. You’re good.

But—and this trips people up constantly—in 2011, they switched everything to 8×180mm.

Know what that means? Wheels off a 2012 Silverado won’t fit your ’05. At all. Even though they’re both “eight-lug Chevy HD wheels.”

I’ve watched people try to force the wrong pattern. Doesn’t work. Save yourself the headache.

Why Eight Lugs Instead of Five or Six?

Your truck hauls weight. Serious weight.

Five lug work fine on a Civic. Six lugs handle a 1500 half-ton. But when you’re pulling twelve thousand pounds or loading three thousand pounds in the bed?

Eight lugs spread that load. More contact points. Safer. Stronger.

Light-duty trucks stick with six. Heavy-duty bumps up to eight. Simple as that.

The “6.5 inch” measurement:

Imagine drawing a circle that touches the center of each lug hole. That circle? Six and a half inches across. Or 165.1 millimeters if you’re reading a metric spec sheet.

This number has to match perfectly. Like, dead-on. An 8×170mm wheel won’t fit an 8×165.1mm hub even though they’re “close.” The holes just miss. By a few millimeters. Which might as well be a mile when you’re trying to bolt something on.

Why GM stuck with this pattern for so long:

Parts compatibility. A wheel that fit a ’99 Silverado worked on an ’05. Worked on an ’08 Sierra. Worked on Suburbans, Avalanches, even Hummer H2s.

Made life easier for everyone. Aftermarket companies could design one wheel for a dozen different trucks. Customers had tons of options.

Then 2011 happened, and they changed everything. Thanks, GM.

What Actually Came on Your Truck From the Factory

Depends which trim you bought.

Basic Work Truck

You got 16×6.5-inch steelies. Narrow wheels. Built for hauling lumber and not much else.

Offset was +28mm. Tires were probably 245/75R16.

Boring? Yeah. But tough as hell. I’ve seen these wheels take abuse that would crack fancy aluminum rims.

LT or LS Trim

Slightly better. 16×7-inch wheels. Still pretty basic.

Same offset. Tires bumped up to 265/75R16. A little more meat on them.

HD or Off-Road Package

Now we’re talking. 17×7.5-inch wheels. Usually, aluminum instead of steel.

Offset dropped to +18mm or +25mm. More aggressive stance. Better for off-road.

Tires were 265/70R17. Taller sidewall. Could handle rocks and ruts better.

All of them shared the 8×165.1mm bolt pattern. Doesn’t matter which trim. Pattern’s the same.

Width and offset changed. But the bolt pattern? Consistent across the board.

The Other Numbers That Actually Matter

Bolt pattern’s just the start. Three more measurements determine whether a wheel fits or not.

Hub Bore: 124.1mm

This is the hole in the center of the wheel. Needs to slip over the hub on your truck.

Your ’05 Silverado’s hub measures 124.1 millimeters.

The wheel’s center hole is smaller than that? Won’t fit. Can’t force it.

Is the wheel’s center hole bigger? It’ll slide on, but you need hub-centric rings to fill the gap. Without those rings, the wheel won’t center properly. You’ll feel it shake at highway speed.

Had a customer once who mounted wheels with oversized bores. No rings. The thing vibrated so badly at sixty miles per hour, he thought his transmission was failing. Added twenty-dollar hub rings. The problem vanished instantly.

Lug Nuts: M14×1.5

Your truck uses fourteen-millimeter lug nuts with 1.5-millimeter thread pitch.

This matters when you buy aftermarket wheels. Some wheels need different lug nut styles. Factory GM wheels use conical seat nuts. Some aftermarket wheels use mag-style or tuner-style.

Wrong lug nuts won’t seat right. That’s dangerous. They’ll back off while you’re driving.

Always match the lug nut to the wheel. Most aftermarket wheels come with the right nuts. But not always. Check before you buy.

Offset: How Far In or Out Your Wheels Sit

Factory offset on your truck ranges from +18mm to +30mm, depending on trim.

Positive offset means the mounting surface is closer to the outside of the wheel. The wheel tucks in more.

A lower offset (or negative offset) means the wheel sticks out further. More aggressive look.

Why this matters:

Too much positive offset (wheel too far in): Can hit suspension parts. Especially with wider tires.

Too much negative offset (wheel too far out): Rubs fenders. Puts stress on wheel bearings. Looks cool until your tire chews through your fender liner.

Most guys installing lifts and big tires run +10mm to +18mm offset. More aggressive than stock but not crazy.

Go negative offset or zero, you’re probably gonna need fender trimming or flares.

True Story: When You Don’t Check First

Two years back. Customer walks in. Got a set of “Chevy truck wheels” off Facebook Marketplace. Four hundred bucks. Looked like a steal.

Bring ’em to my shop to mount tires.

I grab one. Walk it over to his truck. It’s a 2005 Silverado 2500HD.

Line it up. Holes are off. Not even close.

Check the pattern. 8×180mm.

His truck needs 8×165.1mm.

About a fifteen millimeter difference in diameter. Doesn’t sound like much. But might as well be a foot when you’re trying to line up bolt holes.

They don’t fit. Can’t make ’em fit. No adapter, no spacer, nothing’s gonna work.

He tried returning them. The seller ghosted him. Posted them on Craigslist. Sold for two hundred bucks.

Lost two hundred dollars in one afternoon.

All because he didn’t ask one question before buying: “What year truck are these off of?”

Could’ve saved himself the whole mess.

The lesson? Always verify. Don’t assume. “Chevy HD wheels” isn’t specific enough. Ask the year. Ask the model. Check the pattern before you hand over cash.

Which Other GM Trucks Use the Same Pattern?

Good news here. Lots of GM vehicles from that era share the 8×6.5 pattern.

Gives you options when shopping for wheels.

Compatible trucks and SUVs (roughly ’99-2010):

Chevy Silverado 2500HD? Yep.

Silverado 3500 and 3500HD? Yep.

GMC Sierra 2500HD? Absolutely.

Sierra 3500 and 3500HD? Yeah.

Suburban 2500 (certain years)? Some of them.

Avalanche 2500 (2002-2006)? Yep.

Hummer H2 (2003-2009)? They work too.

But here’s the catch: Just because the bolt pattern matches doesn’t guarantee a perfect fit.

You still gotta check:

- Hub bore (some differ)

- Offset (varies by model)

- Brake clearance (bigger brakes need more room)

- Load rating (must handle your truck’s weight)

I’ve swapped wheels between an ’05 Silverado and an ’08 Sierra with zero issues. Same everything. Bolted right on.

But when someone tried Hummer H2 wheels on their Silverado? Brake calipers hit the inside of the wheel. Wouldn’t clear. Needed spacers to make it work.

So yeah. Bolt pattern’s the first thing to check. Not the only thing.

Ford and Dodge? Nope. Different Animals.

Can’t mix brands here. At least not without adapters.

Ford F-250 and F-350 Super Duty:

Most years run 8×170mm. Close to 8×165.1mm, but not the same. Won’t fit.

Dodge Ram 2500 and 3500:

Gets confusing. Older Rams (pre-2012) used 8×6.5. Same as GM. So technically, those might work.

But starting around 2012, Ram went to 8×165.1mm with different hub bores and offsets. Bolt pattern matches on paper, but fitment’s still questionable.

My advice? Stick with GM wheels for your GM truck. Way less hassle. You know they’ll fit. You know they’re rated for the weight. You’re not guessing.

Yeah, you might find some old Ram wheels that technically bolt on. But do you really wanna risk it? Hub bore might be off. Offset might be weird. Load rating might be too low.

Not worth the gamble when GM wheels are everywhere.

Installing Aftermarket Wheels: What to Watch For

Thinking about upgrading to aftermarket wheels? Here’s what you need to consider:

1. Load Rating

Your 2500HD is a heavy-duty truck. It can carry over 3,000 pounds in the bed and tow 10,000-15,000 pounds depending on configuration.

Your wheels need to be rated for that weight.

Cheap wheels designed for light-duty trucks or SUVs won’t cut it. They’ll bend, crack, or fail under heavy loads.

Look for wheels rated for at least 3,000 pounds per wheel. Many aftermarket HD wheels are rated for 3,500-4,000 pounds.

Don’t cheap out here. I’ve seen cracked wheels from guys who bought light-duty wheels for their 2500HD because “they looked cool.” Not worth the risk.

2. Brake Clearance

Your 2500HD has big brakes. Especially if you have the Duramax diesel or tow package.

Some aftermarket wheels don’t have enough clearance for those big calipers. The wheel hits the caliper, and you can’t bolt it on.

How to check: Most wheel sellers list “brake clearance” specs. Make sure there’s at least 10-15mm of clearance between the caliper and the inside of the wheel.

If you’re buying in person, test-fit one wheel before mounting tires. Better to find out it doesn’t clear BEFORE you’ve spent money on tires.

3. TPMS Compatibility

Your 2005 might have tire pressure monitoring sensors (TPMS), depending on options.

If it does, make sure your new wheels can accommodate the sensors. Most can, but some cheaper wheels don’t have cutouts for the valve stems.

4. Lug Nut Style

Aftermarket wheels often use different lug nut seat types.

Factory GM wheels = conical (cone-shaped) seat

Some aftermarket wheels = mag-style (flat washer) or tuner-style (extended shank)

You MUST match the lug nut to the wheel. Using conical nuts on a mag-style wheel (or vice versa) means they won’t seat properly. That’s dangerous.

When you buy aftermarket wheels, ask the seller what lug nuts they require. Most include them, but not always.

Wheel Spacers: Should You Use Them?

Wheel spacers push your wheels outward, giving you a wider stance.

Pros:

- More aggressive look

- Can clear bigger brake kits

- Easier to fit wider tires without rubbing suspension

Cons:

- Adds stress to wheel bearings

- Requires longer lug studs (for thick spacers)

- Can affect steering feel and stability

- Increases scrub radius (more steering effort)

My take: I’m not a huge fan of spacers on heavy-duty trucks, especially for towing.

If you’re using 1-inch spacers to clear bigger tires on a mall crawler, fine. But if you’re towing 10,000 pounds regularly, I’d rather see you buy wheels with the correct offset from the start.

Spacers aren’t inherently dangerous if they’re quality units and properly installed. But they’re an extra link in the chain that can fail.

If you DO use spacers, get hub-centric ones (not just bolt-on styles) and check them frequently for loosening.

Lift Kits and Wheel Fitment: What Changes

Planning a lift? That changes your wheel options.

With a leveling kit (2-inch front lift):

- You can fit slightly bigger tires (up to 33 inches usually)

- Factory wheels still work fine

- Might need a slight offset change for wider tires

With a 4-6 inch suspension lift:

- Can fit 35-37 inch tires

- Usually need wheels with less positive offset (+10mm to +18mm)

- May need minor trimming for full articulation

With a 6+ inch lift:

- Sky’s the limit on tire size (37s, 40s, etc.)

- Need wheels with a lower offset or spacers

- Definitely need to trim fenders and possibly cut bumpers

Important: Bigger tires change your gear ratios. You’ll lose acceleration and fuel economy. Re-gearing helps but costs $1,500-2,500.

How to Properly Torque Your Lug Nuts

This is basic stuff, but I see people screw it up constantly.

Correct torque spec for 2005 Silverado 2500HD: 140 lb-ft

How to do it right:

- Hand-tighten first: Thread all lug nuts on by hand before using the impact gun.

- Use a torque wrench: Don’t rely on your impact gun’s “feel.” Use a torque wrench set to 140 lb-ft.

- Tighten in a star pattern: Not in a circle. Go across the hub in a star/cross pattern. This ensures even pressure.

- Re-check after 50 miles: Lug nuts can settle. After your first drive, re-torque them. I do this on every wheel I install.

What happens if you over-torque?

- Stripped threads

- Warped brake rotors

- Broken studs

What happens if you under-torque?

- Lug nuts back off while driving

- The wheel comes loose (this is as bad as it sounds)

I had a customer lose a wheel on the highway because some quick-lube place didn’t torque the nuts properly. The truck dropped onto the rotor, grinding to a halt in the middle of traffic. Totaled the truck.

140 lb-ft. Use a torque wrench. Don’t guess.

Common Wheel Fitment Problems (And How to Fix Them)

Problem 1: Vibration at Highway Speed

Cause: Usually one of three things:

- Wheels not hub-centric (need hub rings)

- Bent wheel

- Out-of-balance tire

Fix:

- Check if wheels are hub-centric. If not, buy hub rings for 124.1mm bore.

- Inspect wheels for bends or cracks

- Get tires balanced properly

Problem 2: Rubbing on the Fender or Suspension

Cause:

- Offset too negative (wheels stick out too far)

- Tires too wide for the wheel well

- Suspension compressed (loaded truck, hitting bumps)

Fix:

- Use wheels with more positive offset

- Downsize tires

- Trim the fender liner or install fender flares

- Limit load to prevent excessive compression

Problem 3: Lug Nuts Won’t Tighten Properly

Cause:

- Wrong lug nut style (conical vs mag-seat)

- Damaged threads on wheel or studs

- Over-torqued previously (stripped threads)

Fix:

- Match lug nut style to wheel

- Replace damaged studs or wheels

- Usea thread repair kit if the threads are mildly damaged

Problem 4: Wheel Won’t Fit Over Brake Caliper

Cause: The wheel doesn’t have enough brake clearance

Fix:

- Return wheels and get a different design with more clearance

- Use wheels designed for HD trucks specifically

- If desperate, add thin spacers (but check load rating)

Maintaining Your Wheels and Lug Hardware

Keep your wheels and studs in good shape with basic maintenance:

Every oil change:

- Inspect lug nuts for cracks or rounding

- Check for loose wheels (grab the tire and shake it—shouldn’t have play)

- Look for rust or corrosion on studs

Every 6 months:

- Remove wheels and clean the hub face

- Apply anti-seize to studs (thin coat, don’t go crazy)

- Inspect for cracks in wheels, especially around lug holes

- Re-torque lug nuts to 140 lb-ft

Winter driving:

- Wash wheels regularly to remove road salt

- Check torque more often (temperature changes can affect it)

- Inspect for corrosion, especially if you live in the Rust Belt

Replacing studs: If a stud gets damaged, replace it immediately. Don’t drive on seven lug nuts while one’s missing or broken. You’re putting extra stress on the remaining studs.

Should You Stick with Factory Wheels or Go Aftermarket?

Honest answer? Depends what you’re doing with the truck.

Stick with factory-style wheels if:

- You’re using the truck for work (towing, hauling, construction)

- You want maximum durability and load capacity

- You don’t care about looks

- You want wheels that are easy to replace if damaged

Factory wheels are boring, but they’re tough as nails. I’ve seen factory GM HD wheels take insane abuse and keep going.

Go aftermarket if:

- You want better looks

- You’re building a show truck or weekend warrior

- You need specific fitment for a lift kit

- You want lighter wheels (fuel economy gains)

Just make sure you buy from reputable brands. Method, Fuel, Black Rhino, KMC, Vision—these companies make quality HD wheels.

Avoid cheap, no-name brands from random websites. I’ve seen those wheels crack under normal use.

Where to Buy Wheels for Your 2005 Silverado 2500HD

Local options:

- Tire shops (Discount Tire, Tire Rack, local independents)

- Dealerships (expensive but guaranteed fitment)

- Salvage yards (cheap if you’re patient)

Online options:

- CustomWheelOffset.com (great for checking fitment)

- Tire Rack (good selection, helpful customer service)

- Summit Racing (performance focus)

- eBay / Facebook Marketplace (cheap but risky—inspect carefully)

My recommendation: If it’s your first time buying wheels, go to a tire shop. They’ll measure everything, guarantee fitment, and mount/balance for you.

Once you know what works, buying online can save money. But there’s value in expert help, especially on a heavy-duty truck where safety matters.

Quick Checklist Before You Buy New Wheels

Print this out and take it with you:

✅ Bolt pattern: Must be 8×165.1mm (8×6.5″)

✅ Hub bore: Must be 124.1mm or larger (use rings if larger)

✅ Load rating: Minimum 3,000 lbs per wheel

✅ Offset: +10mm to +30mm (depends on tire size and lift)

✅ Brake clearance: Check with seller or test-fit

✅ Lug nut compatibility: Match seat style to wheel

✅ TPMS compatibility: If your truck has it

✅ Width: Don’t go too wide without checking for rubbing

Run through this list, and you’ll avoid 99% of the problems people run into.

The Bottom Line on Bolt Patterns and Fitment

Look, wheel fitment isn’t rocket science. But it’s also not something you can wing.

Your 2005 Silverado 2500HD uses an 8×6.5 (8×165.1mm) bolt pattern. That’s the foundation of everything else.

Match that pattern, check your hub bore, pick the right offset, torque your lug nuts properly, and you’ll be fine.

Ignore these specs, and you’re either wasting money on wheels that don’t fit, or worse—creating a safety hazard.

I’ve seen wheels fall off trucks. I’ve seen guys crack expensive wheels on the first pothole because they bought cheap junk. I’ve watched people spend thousands fixing suspension damage from rubbing tires.

All preventable.

Do it right the first time. Your truck—and your wallet—will thank you.

Quick Reference: 2005 Silverado 2500HD Wheel Specs

| Specification | Value |

|---|---|

| Bolt Pattern | 8×165.1mm (8×6.5″) |

| Hub Bore | 124.1mm |

| Lug Nut Size | M14×1.5 |

| Lug Nut Torque | 140 lb-ft |

| Factory Offset | +18mm to +30mm |

| Factory Wheel Sizes | 16×6.5, 16×7, 17×7.5 |

| Load Rating (minimum) | 3,000 lbs per wheel |

Frequently Asked Questions

Q: Will 2011+ Silverado 2500HD wheels fit my 2005?

No. GM changed the bolt pattern to 8×180mm starting in 2011. Not compatible without adapters.

Q: Can I use 1500 wheels on my 2500HD?

No. The 1500 uses a 6-lug pattern (6×139.7mm). Completely different.

Q: Do GMC Sierra wheels fit Chevy Silverado?

Yes, as long as they’re from the same generation (1999-2010 for your 2005). Same bolt pattern and hub bore.

Q: What’s the biggest tire I can fit without a lift?

On stock wheels and suspension, you can usually fit up to 285/75R16 or 265/70R17 without major rubbing. Anything bigger needs a lift or leveling kit.

Q: Are hub-centric rings necessary?

If your aftermarket wheels have a larger center bore than 124.1mm, yes. Without them, you’ll feel vibration. They’re cheap ($20-30) and worth it.

Q: Can I use wheel adapters to fit different bolt patterns?

Technically, yes, but I don’t recommend it for a heavy-duty truck that tows. They add stress and potential failure points. Buy wheels with the correct pattern.

Q: How often should I check lug nut torque?

Check after the first 50-100 miles with new wheels, then every oil change or if you’ve had the wheels off for any reason.

Q: What offset should I run with a 6-inch lift?

Generally, +10mm to +18mm works well for lifted trucks with 35-37 inch tires. Lower offsets givea more aggressive stance but may require trimming.

Save this guide. Share it with your truck buddies. And for the love of all that’s holy, check your bolt pattern before you buy wheels.

Stay safe out there. 🛞🔧